California Code of Regulations

Title 24, Part 2, Volume 1 of 2

California Building

Standards Commission

Based on the 2009 International Building Code®

California Code of Regulations

Title 24, Part 2, Volume 1 of 2

California Building

Standards Commission

Based on the 2009 International Building Code®

EFFECTIVE DATE: January 1, 2011

(For Errata and supplements, See History Note Appendix)

Public Domain: U.S. Court of Appeals, Fifth Circuit, 99-40632

2010 California Building Code

California Code of Regulations, Title 24, Volume 1 of Part 2

First Printing: June 2010

ISBN 978-1-58001-974-3

Copyright © 2010

Held by

California Building Standards Commission

2525 Natomas Park Drive, Suite 130

Sacramento, CA 95833-2936

ALL RIGHTS RESERVED. This 2010 California Building Code contains substantial copyrighted material from the 2009 International Building Code, Second Printing, which is a copyrighted work owned by the International Code Council, Inc. Without advance written permission from the copyright owner, no part of this book may be reproduced, distributed or transmitted in any form or by any means, including, without limitation, electronic, optical or mechanical means (by way of example and not limitation, photocopying, or recording by or in an information storage retrieval system). For information on permission to copy material exceeding fair use, please contact: Publications, 4051 West Flossmoor Road, Country Club Hills, IL 60478. Phone 1-888-ICC-SAFE (422-7233).

Trademarks: “International Code Council,” the “International Code Council” logo and the “International Building Code” are trade marks of the International Code Council, Inc.

PRINTED IN THE U.S.A.

This document is Part 2 of 12 parts of the official triennial compilation and publication of the adoptions, amendments and repeal of administrative regulations to California Code of Regulations, Title 24, also referred to as the California Building Standards Code. This Part is known as the California Building Code.

The California Building Standards Code is published in its entirety every three years by order of the California legislature, with supplements published in intervening years. The California legislature delegated authority to various state agencies, boards, commissions and departments to create building regulations to implement the State’s statutes. These building regulations or standards, have the same force of law, and take effect 180 days after their publication unless otherwise stipulated. The California Building Standards Code applies to occupancies in the State of California as annotated.

A city, county or city and county may establish more restrictive building standards reasonably necessary because of local climatic, geological or topographical conditions. Findings of the local condition(s) and the adopted local building standard(s) must be filed with the California Building Standards Commission to become effective and may not be effective sooner than the effective date of this edition of California Building Standards Code. Local building standards that were adopted and applicable to previous editions of the California Building Standards Code do not apply to this edition without appropriate adoption and the required filing.

Should you find publication (e.g., typographical) errors or inconsistencies in this code or wish to offer comments toward improving its format, please address your comments to:

California Building Standards Commission

2525 Natomas Park Drive, Suite 130

Sacramento, CA 95833-2936

Phone: (916) 263-0916

Fax: (916) 263-0959

Web Page: www.bsc.ca.gov

The 2010 California Building Standards Code (Code) was developed through the outstanding collaborative efforts of the Department of Housing and Community Development, the Division of State Architect, the Office of the State Fire Marshal, the Office of Statewide Health Planning and Development, the California Energy Commission, and the Building Standards Commission (Commission).

This collaborative effort included the assistance of the Commission’s Code Advisory Committees and many other volunteers that worked tirelessly to assist the Commission in the production of this Code.

Governor Arnold Schwarzenegger

Members of the Building Standards Commission

Acting Secretary Tom Sheehy – Chair

Isam Hasenin – Vice-Chair

James Barthman

Craig Daley

Susan Dowty

Tony Hoffman

Christina Jamison

Stephen Jensen

Michael Paravagna

Richard Sawhill

Steven Winkel

David Walls – Executive Director

Thomas Morrison – Deputy Executive Director

For questions on California state agency amendments; please refer to the contact list on the following page.

iiiCalifornia Agency Information Contact List

| California Energy Commission | |

| Energy Hotline | (800) 772-3300 |

| or (916) 654-5106 | |

| Building Efficiency Standards | |

| Appliance Efficiency Standards | |

| Compliance Manual/Forms | |

| California State Lands Commission | |

| Marine Oil Terminals | (562) 499-6317 |

| California State Library | |

| Resources and Information | (916) 654-0261 |

| Government Publication Section | (916) 654-0069 |

| Corrections Standards Authority | |

| Local Adult Jail Standards | (916) 324-1914 |

| Local Juvenile Facility Standards | (916) 324-1914 |

| Department of Consumer Affairs–Acupuncture Board | |

| Office Standards | (916) 445-3021 |

| Department of Consumer Affairs–Board of Pharmacy | |

| Pharmacy Standards | (916) 574-7900 |

| Department of Consumer Affairs–Bureau of Barbering And Cosmetology | |

| Barber and Beauty Shop and College Standards | (916) 574-7570 |

| Structural Standards | (800) 952-5210 |

| Department of Consumer Affairs–Bureau of Home Furnishings and Thermal Insulation | |

| Insulation Testing Standards | (916) 574-2041 |

| Department of Consumer Affairs–Structural Pest Control Board | |

| Structural Standards | (800) 737-8188 |

| (916) 561-8708 | |

| Department of Consumer Affairs–Veterinary Medical Board | |

| Veterinary Hospital Standard | (916) 263-2610 |

| Department of Food and Agriculture | |

| Meat and Poultry Packing Plant Standards | (916) 654-1447 |

| Dairy Standards | (916) 654-1447 |

| Department of Public Health | |

| Organized Camps Standards | (916) 449-5661 |

| Public Swimming Pools Standards | (916) 449-5693 |

| Asbestos Standards | (510) 620-2874 |

| Department of Housing and Community Development | |

| Residential–Hotels, Motels, Apartments, Single-Family Dwellings | (916) 445-9471 |

| Permanent Structures in Mobilehome and Special Occupancy Parks | (916) 445-9471 |

| Factory-Built Housing, Manufactured Housing and Commercial Modular | (916) 445-3338 |

| Mobilehomes–Permits and Inspections Northern Region | (916) 225-2501 |

| Southern Region | (951) 782-4420 |

| Employee Housing Standards | (916) 445-9471 |

| Department of Water Resources | |

| Gray Water Installations Standards | (916) 651-9667 |

| Division of the State Architect–Access Compliance | |

| Access Compliance Standards | (916) 445-8100 |

| Division of the State Architect–Structural Safety | |

| Public Schools Standards | (916) 445-8100 |

| Essential Services Building Standards | (916) 445-8100 |

| Community College Standards | (916) 445-8100 |

| Division of the State Architect–State Historical Building Safety Board | |

| Alternative Building Standards | (916) 445-8100 |

| Office of Statewide Health Planning and Development | |

| Hospital Standards | (916) 440-8409 |

| Skilled Nursing Facility Standards | (916) 440-8409 |

| Clinic Standards | (916) 440-8409 |

| Permits | (916) 440-8409 |

| Office of the State Fire Marshal | |

| Code Development and Analysis | (916) 445-8200 |

| Fire Safety Standards | (916) 445-8200 |

| Fireplace Standards | (916) 445-8200 |

| Day-Care Centers Standards | (916) 445-8200 |

| Exit Standards | (916) 445-8200 |

Distilling the code review process down to a methodical, sequential list of considerations is generally problematic. In many cases, related provisions from various chapters of the code must be considered simultaneously, or reconsidered later in the process to arrive at the correct classification or determination. Any number of acceptable alternatives may exist for construction of the building and its specific features. Each choice provided by the code must be evaluated for its specific impact on other aspects of the building's analysis. With a basic understanding of the interrelationship of the various chapters, the practiced code user will make an initial assessment of the building as a first step of the code review process. The following outline may be helpful as a guide for the effective use of the IBC, with the understanding that final resolution of each step is often dependant on subsequent steps.

The following process begins with a brief discussion of the key administrative areas of the code. The process addressing technical provisions is divided into two distinct areas of analysis, the nonstructural provisions of the IBC and the structural provisions. Although reference is not made to all provisions set forth in the IBC, the process is intended to be representative of an approach to using the IBC in an effective manner.

Administrative Provisions

Prior to any analysis based on the technical provisions of the IBC, it is important that the fundamental administrative aspects of the code be reviewed. It is critical that the basis of technical decisions be consistent with the approach established in IBC Chapter 1, including:

Nonstructural Provisions

| Sec. 303 | Group A |

| Sec. 304 | Group B |

| Sec. 305 | Group E |

| Sec. 306 | Group F |

| Sec. 307 | Group H |

| Sec. 308 | Group I |

| Sec. 309 | Group M |

| Sec. 310 | Group R |

| Sec. 311 | Group S |

| Sec. 312 | Group U |

| Sec. 602 | Type of construction based on materials of construction |

| Table 601 | Type of construction based on fire rating of the building elements |

| Sec. 603 | Combustible materials in Type I and II buildings |

| Sec. 504.2 | Story and height increase (reduced type of construction) |

| Sec. 506.3 | Allowable area increase (reduced type of construction) |

| Sec. 507.3 | Unlimited area building (reduced type of construction) |

| Sec. 1018.1 | Elimination of corridor fire-resistance rating |

| Sec. 506 | Single-occupancy building |

| Sec. 508.2 | Multi-occupancy w/accessory occupancies |

| Sec. 508.3 | Multi-occupancy building w/nonseparated occupancies |

| Sec. 508.4 | Multi-occupancy building w/separated occupancies |

| Sec. 706.1 | Use of fire walls |

| Sec. 402 | Covered mall buildings |

| Sec. 403 | High-rise buildings |

| Sec. 404 | Atriums |

| Sec. 405 | Underground buildings |

| Sec. 406 | Motor-vehicle-related occupancies |

| Sec. 407 | Group I-2 occupancies |

| Sec. 408 | Group I-3 occupancies |

| Sec. 411 | Special amusement buildings |

| Sec. 412 | Aircraft-related occupancies |

| Sec. 415 | Group H occupancies |

| Sec. 419 | Live/work units |

| Sec. 420 | Groups I-1, R-1, R-2 and R-3 |

| Sec. 422 | Ambulatory health care facilities |

| Sec. 704 | Structural members |

| Sec. 707 | Fire barriers |

| Sec. 709 | Fire partitions |

| Sec. 710 | Smoke barriers |

| Sec. 711 | Smoke partitions |

| Sec. 712 | Horizontal assemblies |

| Sec. 708 | Shaft enclosures |

| Sec. 713 | Penetrations |

| Sec. 714 | Joint systems |

| Sec. 715 | Opening protectives |

| Sec. 716 | Ducts and air transfer openings |

| Sec. 1005.1 | Egress width and distribution |

| Sec. 1006.3 | Emergency lighting |

| Sec. 1007 | Accessible means of egress |

| Sec. 1008.1.2 | Door swing |

| Sec. 1008.1.9 | Door operations |

| Sec. 1008.1.10 | Panic hardware |

| Sec. 1009.1 | Stairway width |

| Sec. 1009.4 | Stairway treads and risers |

| Sec. 1011 | Exit signs |

| Sec. 1012 | Stairway and ramp handrails |

| Sec. 1013 | Guards |

| Sec. 1014.2 | Egress through intervening spaces |

| Sec. 1014.3 | Common path of egress travel |

| Sec. 1015.1 | Number of exit or exit access doorways |

| Sec. 1015.2 | Egress separation |

| Sec. 1016.1 | Travel distance |

| Sec. 1018.1 | Corridor construction |

| Sec. 1021 | Number of exits |

| Sec. 1022 | Vertical exit enclosures |

| Sec. 1023 | Exit passageways |

| Sec. 1025 | Horizontal exits |

| Sec. 1026 | Exterior exit stairways |

| Sec. 1027 | Exit discharge |

| Sec. 1028 | Egress from assembly occupancies |

| Sec. 410 | Stages and platforms |

| Sec. 413 | Combustible storage |

| Sec. 414 | Hazardous materials |

| Sec. 416 | Application of flammable finishes |

Structural Provisions

General Requirements

The 2009 IBC reference the national load standard, Minimum Design Loads for Buildings and Other Structures (ASCE/SEI 7—O5) with Supplement Number 2.

Determine the applicable design loads that the building structure is expected to be subjected to. Code prescribed loads are given in Chapter 16 and the referenced standard, ASCE/SEI 7. The code prescribed minimum live loads are given in IBC Table 1607.1.

The various code prescribed loads are probabilistic in nature. Environmental loads, such as flood, rain, snow, seismic and wind vary based on the location of the building site. The following table gives the IBC section and ASCE/SEI 7 chapter for various types of load.

| REFERENCED IBC SECTIONS AND ASCE/SEI 7 CHAPTERS FOR LOADS | ||

|---|---|---|

| TYPE OF LOAD | IBC SECTION | ASCE/SEI 7 CHAPTER |

| Dead loads | Section 1606 | Chapter 3 |

| Live loads | Section 1607, Table 1607.1 | Chapter 4 |

| Snow loads | Section 1608 | Chapter 7 |

| Wind loads | Section 1609 | Chapter 6 |

| Soil lateral loads | Section 1610 | Chapter 3 |

| Rain loads | Section 1611 | Chapter 8 |

| Flood loads | Section 1612 | Chapter 51 |

| Earthquake loads | Section 1613 | Chapter 11-22 |

| 1 Section 1612 references ASCE 24 which references Chapter 5 of ASCE/SEI 7 | ||

The structural design begins with the selection of the type of structural materials to be used to support the building. Structural framing systems are constructed of concrete, masonry, steel or wood. Some miscellaneous or specialty structures and components, such as awnings, canopies and cladding, are often constructed of aluminum.

The design of various structural materials is covered in specific material chapters in the code which in turn reference design standards for the type of material involved. The referenced standards in the 2009 IBC for the structural materials are shown in the following table:

| STRUCTURAL DESIGN STANDARDS FOR STRUCTURAL MATERIALS1 | ||

|---|---|---|

| MATERIAL | IBC/CBC CHAPTER | REFERENCED STANDARD |

| Concrete | 19 | ACI 318—08 Building Code Requirements for Structural Concrete |

| Aluminum | 20 | ADM 1—05 Aluminum Design Manual |

| Masonry | 21 | TMS 402-08/ACI 530-08/ASCE 5-08 Building Code Requirements and Specification for Masonry Structures (MSJC Code) |

| Steel | 22 | AISC 360—05 Specification for Structural Steel Buildings AISC 341—05 Seismic Provisions for Structural Steel Buildings, including Supplement No. 1 dated 2006 AISI S100—2007 North American Specification for the Design of Cold-Formed Steel Structural Members |

| Wood | 23 | AF&PA NDS—05 National Design Specification (NDS) for Wood Construction with 2005 Supplement AF&PA SDPWS—08 Special Design Provisions for Wind and Seismic |

| 1. The above table shows the main structural design standards for these structural materials. For a complete list of referenced standards, see IBC Chapter 35. | ||

Once the applicable loads are determined, the structural system of the building must be analyzed to determine the effects of the governing gravity and lateral loads that act on the structure. The structural system of a typical building consists of the roof and floor systems, walls, beams and columns, and the foundation. From the structural analysis, the next step is to design the structural members, elements and systems to provide the minimum level of resistance in accordance with the various load combinations prescribed in Section 1605.

Once the structural elements and systems are designed, the next step is to detail the load transfer connections to provide a complete load path from the point of origin to the resisting element. In general, the ultimate resisting element of buildings and structures is the foundation and supporting ground. The final step is to prepare a complete set of construction documents as required by Sections 107 and 1603. Construction documents are defined in Section 202 as "Written, graphic and pictorial documents prepared or assembled for describing the design, location and physical characteristics of the elements of a project necessary for obtaining a building permit." In general, construction documents consist of plans, specifications and calculations.

Section 1603.1 requires construction documents to show the size, section and relative locations of structural members with floor levels, column centers and offsets dimensioned. Design loads required by Sections 1603.1.1 through 1603.1.9 must be indicated on the construction documents. If complete construction documents consisting of plans, specifications and calculations are provided, the items listed in Sections 1603.1.1 through 1603.9 are generally included.

xThe exception permits construction documents for buildings constructed in accordance with the conventional light-frame construction provisions of Section 2308 need only indicate the following:

Floor and roof live loads

Ground snow load, Pg.

Basic (3-second gust) wind speed (mph) and wind exposure category.

Seismic design category and site class.

Flood design data where sited in flood hazard areas

Design load-bearing values of soils.

General Requirements

Determine the occupancy category of the building based on Table 1604.5.

Where a structure is occupied by two or more occupancies that are not the same occupancy category, the building must be classified in the highest occupancy category corresponding to the various occupancies.

Where structures have two or more portions that are structurally separated, each separate portion should be separately classified.

Where a separated portion of a structure provides required access or egress from another portion of the building with a higher occupancy category, both portions of the building must be assigned the higher occupancy category.

Where a separated portion of a structure shares life safety components with another portion of the building with a higher occupancy category, both portions of the building must be assigned the higher occupancy category.

Determine uniformly distributed and concentrated floor live load for the floor areas of the building in accordance with Section 1603.1.1 and Table 1607.1.

Floor live load reduction in accordance with Section 1607.9 should be indicated for each type of live load that is reduced.

Determine the roof live load for roof areas in accordance with Section 1607.11.

Roof live load reduction in accordance with Section 1607.11.2 should be indicated for roof live loads that are reduced.

Determine the ground snow load, Pg, based on the location of the building site in accordance with Figure 1608.2 for the contiguous United States and Table 1608.2 for Alaska.

In areas where the ground snow load, Pg, exceeds 10 psf, the following information should be determined:

Determine the following information related to wind loads in accordance with Section 1603.1.4:

Determine the following information related to seismic loads regardless of whether seismic loads govern the design of the lateral-force-resisting system of the building:

The design load bearing values of soils shall be shown on the construction documents in accordance with Section 1603.1.6.

Determine any special loads that are applicable to the design of the building, structure or portions thereof along with the specific section of the code that addresses the special loading condition in accordance with Section 1603.1.8.

Buildings and other structures and portions thereof are required to be designed to resist the load combinations specified in Section 1605.2 or 1605.3 and Chapters 18 through 23, and the special seismic load combinations with overstrength as required by Section 1605.1 and ASCE/SEI 7.

Lateral-force-resisting systems are required to conform to the seismic detailing requirements of the code and ASCE/SEI 7 (excluding Chapter 14 and Appendix 11A) even when wind load effects are greater than seismic load effects. See Section 1604.10.

Structural systems and members shall be designed to have adequate stiffiness to limit deflections and lateral drift. The deflection of structural members shall not exceed the more restrictive of the limitations of Sections 1604.3.2 through 1604.3.6 or that permitted by Table 1604.3. Structural systems shall be designed to have adequate stiffness to limit deformation and lateral drift due to earthquake loading in accordance with Section 12.12.1 of ASCE/SEI 7.

A foundation system must be designed that provides adequate support for gravity and lateral loads. Walls of buildings of conventional light frame construction, as defined in Section 202, are permitted to be supported by footings constructed in accordance with Table 1809.7. Otherwise, the foundation system must be designed in accordance with other provisions of Chapter 18. The following table gives a summary of applicable sections for foundation systems.

| FOUNDATION REQUIREMENTS | |

|---|---|

| SUBJECT | IBC SECTION |

| Presumptive load-bearing values of soils | 1806, Table 1806.2 |

| Foundation walls, retaining walls and embedded posts & poles | 1807 |

| General requirements for foundations | 1808 |

| Minimum concrete specified concrete strength | Table 1808.8.1 |

| Minimum concrete cover | Table 1808.8.2 |

| Shallow foundations (footings) | 1809 |

| Prescriptive footings for light frame walls | Table 1809.7 |

| Deep foundations | 1810 |

A geotechnical investigation is required where required by Section 1803.2 unless the building official determines that a soils investigation is not required in accordance with the exception. A geotechnical investigation is required for buildings assigned to Seismic Design Categories C, D, E and F in accordance with Sections 1803.5.11 and 1803.5.12.

Requirements for excavation, grading and fill related to foundation construction are covered in Section 1804. General requirements for site grading are covered in Appendix J.

Where required by Section 1612.5, buildings located in flood hazard areas as established in Section 1612.3 are required to provide documentation that includes the following information regardless of whether flood loads govern the design of the building:

Where special inspection, special inspection for seismic resistance, or structural testing for seismic resistance is required by Section 1704, 1707 or 1708, the registered design professional in responsible charge is required to prepare a statement of special inspections in accordance with Section 1705. The statement of special inspections must be submitted by the permit applicant as a condition of permit issuance in accordance with Section 106.1.

A statement of special inspections is not required for structures designed and constructed in accordance with the conventional construction provisions of Section 2308 unless specific components in the structure require special inspection.

The statement of special inspections is permitted to be prepared by a qualified person approved by the building official for construction not designed by a registered design professional.

| SPECIAL INSPECTION REQUIREMENTS | ||

|---|---|---|

| TYPE OF SPECIAL INSPECTION | APPLICABLE SECTION | REQUIRED VERIFICATION AND INSPECTION |

| Steel construction | 1704.3 | Table 1704.3 |

| Concrete construction | 1704.4 | Table 1704.4 |

| Masonry construction | ||

| Level 1 | 1704.5 | Table 1704.5.1 |

| Level 2 | Table 1704.5.3 | |

| Wood construction | 1704.6 | — |

| Soils | 1704.7 | Table 1704.7 |

| Driven deep foundations | 1704.8 | Table 1704.8 |

| Cast in place deep foundations | 1704.9 | Table 1704.9 |

| Helical pile foundations | 1704.10 | — |

| Vertical masonry foundations | 1704.11 | — |

| 1704.5 | ||

| Sprayed fire resistant materials | 1704.12 | — |

| Mastic and intumescent fire resistive coatings | 1704.13 | — |

| Exterior insulation and finish (EIFS) systems | 1704.14 | — |

| Special cases | 1704.15 | — |

| Smoke control systems | 1704.16 | — |

| Where required by the provisions of Section 1709.2 or 1709.3, the owner shall employ a registered design professional to perform structural observations as defined in Section 1702. At the conclusion of the work included in the permit, the structural observer shall submit a written statement to the building official that identifies any reported deficiencies that have not been resolved. | ||

Section 1706.1 requires special inspections for wind requirements based on wind speed and exposure category as prescribed in Section 1706.2 through 1706.4, unless exempted by the exceptions to Section 1704.1.

Section 1707.1 requires special inspections for seismic resistance based on seismic design category as prescribed in Sections 1707.2 through 1707.9, unless exempted by the exceptions of Section 1704.1 or 1705.3.

Section 1708.1 requires specific testing and qualification for seismic resistance as prescribed in Sections 1708.2 through 1708.5, unless exempted from special inspections by the exceptions of Section 1704.1 and 1705.3:

Where required by the provisions of Section 1710.2 or 1710.3 the owner is required to employ a registered design professional to perform structural observations as defined in Section 1702. Section 1710.2 requires structural observations for seismic resistance for certain structures assigned to Seismic Design Category D, E or F; Section 1710.3 requires structural observations for wind requirements for certain structures sited where the wind speed exceeds 110 mph.

At the conclusion of the work included in the permit, the structural observer is required to submit a written statement to the building official that identifies any reported deficiencies that have not been resolved.

Prior to the commencement of observations, the structural observer is required to submit a written statement to the building official identifying the structural observations.

At the conclusion of the work included in the permit, the structural observer is required to submit a written statement to the building official indicating what site visits have been made, identifies any deficiencies that have not been resolved.

Section 1709 requires each contractor responsible for the construction of a main wind-or seismic-force-resisting system, designated seismic system or a wind- or seismic-resisting component listed in the statement of special inspections is required to submit a written statement of responsibility to the building official and the owner prior to the commencement of work on the system or component. (The term “designated seismic system” is defined in Section 1702 and Section 11.2 of ASCE/SEI 7). The contractor’s statement of responsibility is required to acknowledge awareness of the special requirements contained in the statement of special inspections.

Construction of foundations or other part of a building is permitted before the construction documents for the whole building or structure have been submitted, provided adequate information has been filed. The holder of such permit for the foundation or other part of a building proceeds at their own risk and without assurance that a permit for the entire structure will be granted.

Work must be constructed in accordance with the approved construction documents and any changes made during construction that are not in compliance with the approved construction documents must be resubmitted for approval as amended construction documents.

Deferred submittals are items that are not submitted at the time of permit application and must have the prior approval of the building official in accordance with Section 107.3.4.2. The registered design professional in responsible charge is required to list the deferred submittals on the construction documents for review by the building official. Documents for deferred submittal items must be reviewed by the registered design professional in responsible charge who will forward them to the building official with a notation indicating the they have been reviewed and are in general conformance with the design of the building.

To distinguish between model code language and the incorporated California amendments, including exclusive California standards, California amendments will appear in italics.

[BSC] This symbol within a section identifies which State agency(s), by its “acronym,”has amended a section of the model code.

| Legend of Acronyms of Adopting State Agencies | |

|---|---|

| BSC | California Building Standards Commission |

| SFM | Office of the State Fire Marshal |

| HCD | Department of Housing and Community Development |

| DSA-AC | Division of the State Architect-Access Compliance |

| DSA-SS | Division of the State Architect-Structural Safety |

| DSA-SS/CC | Division of the State Architect-Structural Safety/Community Colleges |

| OSHPD | Office of Statewide Health Planning and Development |

| CSA | Corrections Standards Authority |

| DPH | Department of Public Health |

| AGR | Department of Food and Agriculture |

| CEC | California Energy Commission |

| CA | Department of Consumer Affairs: Board of Barbering and Cosmetology Board of Examiners in Veterinary Medicine Board of Pharmacy Acupuncture Board Bureau of Home Furnishings Structural Pest Control Board |

| SL | State Librarian |

| SLC | State Lands Commission |

| DWR | Department of Water Resources |

Symbols in the margins indicate the status of code changes as follows:

This symbol indicates that a change has been made to a California amendment.

This symbol indicates California deletion of California language.

xv xviFormat of the California Matrix Adoption Tables

The matrix adoption tables, which follow, show the user which state agencies have adopted and/or amended given sections of the model code. The building application determines which state agency’s adoptions apply. See Section’s 102 through 114 for building applications and enforcement responsibilities.

Agencies are grouped together, based on either local or state enforcement responsibilities. For example, regulations from SFM are enforced both at the state and local levels; therefore, SFM is listed twice in each adoption table indicating state enforcement responsibilities and local enforcement responsibilities.

The side headings identify the scope of state agencies’ adoption as follows:

Adopt the entire IBC chapter without state amendments.

If there is an “X” under a particular state agency’s acronym on this row; this means that particular state agency has adopted the entire model code chapter without any state amendments.

Example:

| Adopting agency | BSC | SFM | HCD | DSA | OSHPD | CSA | DPH | AGR | DWR | CA | SL | SLC | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 1-AC | AC | SS | SS/CC | 1 | 2 | 3 | 4 | ||||||||||

| Adopt entire chapter | X | ||||||||||||||||||

| Adopt entire chapter as amended (amended sections listed below) | S | A | M | P | L | E | |||||||||||||

| Adopt only those sections that are listed below | |||||||||||||||||||

| Chapter/Section | |||||||||||||||||||

Adopt the entire IBC chapter as amended, state-amended sections are listed below:

If there is an “X” under a particular state agency’s acronym on this row, it means that particular state agency has adopted the entire model code chapter; with state amendments.

Each state-amended section that the agency has added to that particular chapter is listed. There will be an “X” in the column, by that particular section, under the agency’s acronym, as well as an “X” by each section that the agency has adopted.

Example:

| Adopting agency | BSC | SFM | HCD | DSA | OSHPD | CSA | DPH | AGR | DWR | CA | SL | SLC | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 1-AC | AC | SS | SS/CC | 1 | 2 | 3 | 4 | ||||||||||

| Adopting entire chapter | |||||||||||||||||||

| Adopt entire chapter as amended (amended sections listed below) | X | ||||||||||||||||||

| Adopt only those sections that are listed below | S | A | M | P | L | E | |||||||||||||

| Chapter/Section | |||||||||||||||||||

| 202 | X | ||||||||||||||||||

Adopt only those sections that are listed below:

If there is an “X” under a particular state agency’s acronym on this row, it means that particular state agency is adopting only specific model code or state-amended sections within this chapter. There will be an “X” in the column under the agency’s acronym, as well as an “X” by each section that the agency has adopted.

Example:

| Adopting agency | BSC | SFM | HCD | DSA | OSHPD | CSA | DPH | AGR | DWR | CA | SL | SLC | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 1-AC | AC | SS | SS/CC | 1 | 2 | 3 | 4 | ||||||||||

| Adopt entire chapter | |||||||||||||||||||

| Adopt entire chapter as amended (amended sections listed below) | |||||||||||||||||||

| Adopt only those sections that are listed below | X | X | S | A | M | P | L | E | |||||||||||

| Chapter 1 | |||||||||||||||||||

| 202 | X | X | S | A | M | P | L | E | |||||||||||

| 202 | X | X | C | O | N | T. | |||||||||||||

| 203 | X | X | |||||||||||||||||

| 203 | X | X | |||||||||||||||||

The International Codes are designed and promulgated to be adopted by reference by ordinance. Jurisdictions wishing to adopt the 2010 California Building Code as an enforceable regulation governing structures and premises should ensure that certain factual information is included in the adopting ordinance at the time adoption is being considered by the appropriate governmental body. The following sample adoption ordinance addresses several key elements of a code adoption ordinance, including the information required for insertion into the code text.

An ordinance of the [JURISDICTION] adopting the 2010 edition of the California Building Code, regulating and governing the conditions and maintenance of all property, buildings and structures; by providing the standards for supplied utilities and facilities and other physical things and conditions essential to ensure that structures are safe, sanitary and fit for occupation and use; and the condemnation of buildings and structures unfit for human occupancy and use and the demolition of such structures in the [JURISDICTION]; providing for the issuance of permits and collection of fees therefor; repealing Ordinance No.— of the [JURISDICTION] and all other ordinances and parts of the ordinances in conflict therewith.

The [GOVERNING BODY] of the [JURISDICTION] does ordain as follows:

Section 1. That a certain document, three (3) copies of which are on file in the office of the [TITLE OF JURISDICTION’S KEEPER OF RECORDS] of [NAME OF JURISDICTION], being marked and designated as the California Building Code, 2010 edition, including Appendix Chapters [FILL IN THE APPENDIX CHAPTERS BEING ADOPTED] (see California Building Code Section 101.2.1, 2010 edition), as published by the International Code Council, be and is hereby adopted as the Building Code of the [JURISDICTION], in the State of California for regulating and governing the conditions and maintenance of all property, buildings and structures; by providing the standards for supplied utilities and facilities and other physical things and conditions essential to ensure that structures are safe, sanitary and fit for occupation and use; and the condemnation of buildings and structures unfit for human occupancy and use and the demolition of such structures as herein provided; providing for the issuance of permits and collection of fees therefor; and each and all of the regulations, provisions, penalties, conditions and terms of said Buildings Code on file in the office of the [JURISDICTION] are hereby referred to, adopted, and made a part hereof, as if fully set out in this ordinance, with the additions, insertions, deletions and changes, if any, prescribed in Section 2 of this ordinance.

Section 2. The following sections are hereby revised:

Section 101.1. Insert: [NAME OF JURISDICTION]

Section 1612.3. Insert: [NAME OF JURISDICTION]

Section 1612.3. Insert: [DATE OF ISSUANCE]

Section 3412.2. Insert: [DATE IN ONE LOCATION]

Section 3. That Ordinance No. — of [JURISDICTION] entitled [FILL IN HERE THE COMPLETE TITLE OF THE ORDINANCE OR ORDINANCES IN EFFECT AT THE PRESENT TIME SO THAT THEY WILL BE REPEALED BY DEFINITE MENTION] and all other ordinances or parts of ordinances in conflict herewith are hereby repealed.

Section 4. That if any section, subsection, sentence, clause or phrase of this ordinance is, for any reason, held to be unconstitutional, such decision shall not affect the validity of the remaining portions of this ordinance. The [GOVERNING BODY] hereby declares that it would have passed this ordinance, and each section, subsection, clause or phrase thereof, irrespective of the fact that any one or more sections, subsections, sentences, clauses and phrases be declared unconstitutional.

Section 5. That nothing in this ordinance or in the Building Code hereby adopted shall be construed to affect any suit or proceeding impending in any court, or any rights acquired, or liability incurred, or any cause or causes of action acquired or existing, under any act or ordinance hereby repealed as cited in Section 3 of this ordinance; nor shall any just or legal right or remedy of any character be lost, impaired or affected by this ordinance.

Section 6. That the [JURISDICTION'S KEEPER OF RECORDS] is hereby ordered and directed to cause this ordinance to be published. (An additional provision may be required to direct the number of times the ordinance is to be published and to specify that it is to be in a newspaper in general circulation. Posting may also be required.)

Section 7. That this ordinance and the rules, regulations, provisions, requirements, orders and matters established and adopted hereby shall take effect and be in full force and effect [TIME PERIOD] from and after the date of its final passage and adoption.

xix xx| VOLUME 1 | ||

| CHAPTER 1 SCOPE AND ADMINISTRATION | 3 | |

| DIVISION I CALIFORNIA ADMINISTRATION | 3 | |

| Section | ||

| 1.1 | General | 3 |

| 1.2 | Building Standards Commission | 5 |

| 1.3 | Corrections Standards Authority | 6 |

| 1.4 | Department of Consumer Affairs | 6 |

| 1.5 | Reserved | 7 |

| 1.6 | Department of Food and Agriculture | 7 |

| 1.7 | California Department of Public Health | 7 |

| 1.8 | Department of Housing and Community Development | 7 |

| 1.8.2 | Authority and Abbreviations | 7 |

| 1.8.3 | Local Enforcing Agency | 8 |

| 1.8.4 | Permits, Fees, Applications and Inspections | 9 |

| 1.8.5 | Right-of-Entry for Enforcement | 10 |

| 1.8.6 | Local Modification by ordinance or Regulation | 10 |

| 1.8.7 | Alternate Materials, Designs, Tests and Methods of Construction | 10 |

| 1.8.8 | Appeals Board | 11 |

| 1.8.9 | Unsafe Buildings or Structures | 12 |

| 1.8.10 | Other Building Regulations | 12 |

| 1.9 | Division of the State Architect | 12 |

| 1.10 | Office of Statewide Health Planning and Development | 15 |

| 1.11 | Office of the State Fire Marshal | 16 |

| 1.12 | State Librarian | 20 |

| 1.13 | Reserved | 20 |

| 1.14 | California State Lands Commission | 20 |

| DIVISION II SCOPE AND ADMINISTRATION | 21 | |

| 101 | General | 21 |

| 102 | Applicability | 21 |

| 103 | Department of Building Safety | 22 |

| 104 | Duties and Powers of Building Officials | 22 |

| 105 | Permits | 23 |

| 106 | Floor and Roof Design Loads | 25 |

| 107 | Submittal Documents | 25 |

| 108 | Temporary Structures and Uses | 27 |

| 109 | Fees | 27 |

| 110 | Inspections | 27 |

| 111 | Certificate of Occupancy | 28 |

| 112 | Service Utilities | 29 |

| 113 | Board of Appeals | 29 |

| 114 | Violations | 29 |

| 115 | Stop Work Order | 29 |

| 116 | Unsafe Structures and Equipment | 29 |

| CHAPTER 2 DEFINITIONS | 39 | |

| Section | ||

| 201 | General | 39 |

| 202 | Definitions | 39 |

| CHAPTER 3 USE AND OCCUPANCY CLASSIFICATION | 59 | |

| Section | ||

| 301 | General | 59 |

| 302 | Classification | 59 |

| 303 | Assembly Group A | 59 |

| 304 | Business Group B | 60 |

| 305 | Educational Group E | 60 |

| 306 | Factory Group F | 61 |

| 307 | High-Hazard Group H | 61 |

| 308 | Institutional Group I | 70 |

| 309 | Mercantile Group M | 71 |

| 310 | Residential Group R | 71 |

| 311 | Storage Group S | 74 |

| 312 | Utility and Miscellaneous Group U | 75 |

| 313 | Laboratories Group L [SFM] | 75 |

| CHAPTER 4 SPECIAL DETAILED REQUIREMENTS BASED ON USE AND OCCUPANCY | 81 | |

| Section | ||

| 401 | Scope | 81 |

| 402 | Covered Mall and Open Mall Buildings | 81 |

| 403 | High-Rise Buildings and Group I-2 Occupancies Having Occupied Floors Located more than 75 Feet Above the Lowest Level of Fire Department Vehicle Access | 84 |

| 404 | Atriums | 88 |

| 405 | Underground Buildings | 88 |

| 406 | Motor-Vehicle-Related Occupancies | 89 |

| 407 | Group I-2 | 93 |

| 408 | Group I-3 | 96 |

| 409 | Motion Picture Projection Rooms | 99 |

| 410 | Stages and Platforms | 100 |

| 411 | Special Amusement Buildings | 102 |

| 412 | Aircraft-Related Occupancies | 102 |

| 413 | Combustible Storage | 105 |

| 414 | Hazardous Materials | 105 |

| 415 | Groups H-1, H-2, H-3, H-4 and H-5 | 109 |

| 416 | Application of Flammable Finishes | 122 |

| 417 | Drying Rooms | 122 |

| 418 | Organic Coatings | 122 |

| 419 | Live/Work Units | 123 |

| 420 | Groups R-1, R-2, R-2.1, R-3, R-3.1 and R-4 | 123 |

| 421 | Hydrogen Cutoff Rooms | 124 |

| 422 | Ambulatory Health Care Facilities | 125 |

| 423 | Storm Shelters | 125 |

| 424 | Special Provisions for Residential Hotels [HCD 1 & HCD 1-AC] | 125 |

| 425 | Special Provisions for Licensed 24-Hour Care Facilities in a Group R-2.1, R-3.1, R-4 [SFM] | 125 |

| 426 | Group I-4 [SFM] | 128 |

| 427 | Reserved | 129 |

| 428 | Reserved | 129 |

| 429 | Reserved | 129 |

| 430 | Horse Racing Stables [SFM] | 129 |

| 431 | Pet Kennels [SFM] | 129 |

| 432 | Combustion Engines and Gas Turbines [SFM] | 129 |

| 433 | Fixed Guideway Transit Systems [SFM] | 130 |

| 434 | Explosives [SFM] | 133 |

| 435 | Reserved | 136 |

| 436 | Winery Caves [SFM] | 136 |

| 437 | Reserved | 137 |

| 438 | Reserved | 137 |

| 439 | Public Libraries [SL AND SFM] | 137 |

| 440 | Group C [SFM] | 138 |

| 441 | Reserved | 140 |

| 442 | Group E [SFM] | 140 |

| 443 | Group L [SFM] | 141 |

| 444 | Reserved | 144 |

| 445 | Large Family Day-Care Homes [SFM] | 144 |

| CHAPTER 5 GENERAL BUILDING HEIGHTS AND AREAS | 149 | |

| Section | ||

| 501 | General | 149 |

| 502 | Definitions | 149 |

| 503 | General Building Height and Area Limitations | 149 |

| 504 | Building Height | 149 |

| 505 | Mezzanines | 151 |

| 506 | Building Area Modifications | 152 |

| 507 | Unlimited Area Buildings | 153 |

| 508 | Mixed Use and Occupancy | 154 |

| 509 | Special Provisions | 156 |

| CHAPTER 6 TYPES OF CONSTRUCTION | 163 | |

| Section | ||

| 601 | General | 163 |

| 602 | Construction Classification | 163 |

| 603 | Combustible Material in Type I and II Construction | 165 |

| CHAPTER 7 FIRE AND SMOKE PROTECTION FEATURES | 169 | |

| Section | ||

| 701 | General | 169 |

| 702 | Definitions | 169 |

| 703 | Fire-Resistance Ratings and Fire Tests | 170 |

| 704 | Fire-Resistance Rating of Structural Members | 171 |

| 705 | Exterior Walls | 173 |

| 706 | Fire Walls | 177 |

| 707 | Fire Barriers | 179 |

| 708 | Shaft Enclosures | 180 |

| 709 | Fire Partitions | 184 |

| 710 | Smoke Barriers | 185 |

| 711 | Smoke Partitions | 185 |

| 712 | Horizontal Assemblies | 186 |

| 713 | Penetrations | 187 |

| 714 | Fire-Resistant Joint Systems | 189 |

| 715 | Opening Protectives | 190 |

| 716 | Ducts and Air Transfer Openings | 194 |

| 717 | Concealed Spaces | 199 |

| 718 | Fire-Resistance Requirements for Plaster | 201 |

| 719 | Thermal- and Sound-Insulating Materials | 201 |

| 720 | Prescriptive Fire Resistance | 202 |

| 721 | Calculated Fire Resistance | 224 |

| CHAPTER 7A MATERIALS AND CONSTRUCTION METHODS FOR EXTERIOR WILDFIRE EXPOSURE | 255 | |

| Section | ||

| 701A | Scope, Purpose and Application | 255 |

| 702A | Definitions | 256 |

| 703A | Standards of Quality | 256 |

| 704A | Ignition-Resistant Construction | 257 |

| 705A | Roofing | 258 |

| 706A | Vents | 258 |

| 707A | Exterior Covering | 258 |

| 708A | Exterior Windows and Doors | 260 |

| 709A | Decking | 260 |

| 710A | Accessory Structures | 261 |

| CHAPTER 8 INTERIOR FINISHES | 265 | |

| Section | ||

| 801 | General | 265 |

| 802 | Definitions | 265 |

| 803 | Wall and Ceiling Finishes | 265 |

| 804 | Interior Floor Finish | 268 |

| 805 | Combustible Materials in Type I and II Construction | 268 |

| 806 | Decorative Materials and Trim | 269 |

| 807 | Insulation | 269 |

| 808 | Acoustical Ceiling Systems | 269 |

| CHAPTER 9 FIRE PROTECTION SYSTEMS | 277 | |

| Section | ||

| 901 | General | 277 |

| 902 | Definitions | 277 |

| 903 | Automatic Sprinkler Systems | 280 |

| 904 | Alternative Automatic Fire-Extinguishing Systems | 287 |

| 905 | Standpipe Systems | 289 |

| 906 | Portable Fire Extinguishers | 292 |

| 907 | Fire Alarm and Detection Systems | 294 |

| 908 | Emergency Alarm Systems | 308 |

| 909 | Smoke Control Systems | 308 |

| 910 | Smoke and Heat Vents | 315 |

| 911 | Fire Command Center | 317 |

| 912 | Fire Department Connections | 318 |

| 913 | Fire Pumps | 318 |

| 914 | Emergency Responder Safety Features | 319 |

| 915 | Emergency Responder Radio Coverage | 319 |

| CHAPTER 10 MEANS OF EGRESS | 325 | |

| Section | ||

| 1001 | Administration | 325 |

| 1002 | Definitions | 325 |

| 1003 | General Means of Egress | 326 |

| 1004 | Occupant Load | 329 |

| 1005 | Egress Width | 330 |

| 1006 | Means of Egress Illumination | 330 |

| 1007 | Accessible Means of Egress | 331 |

| 1008 | Doors, Gates and Turnstiles | 334 |

| 1009 | Stairways | 340 |

| 1010 | Ramps | 343 |

| 1011 | Exit Signs | 344 |

| 1012 | Handrails | 346 |

| 1013 | Guards | 347 |

| 1014 | Exit Access | 348 |

| 1015 | Exit and Exit Access Doorways | 349 |

| 1016 | Exit Access Travel Distance | 351 |

| 1017 | Aisles | 352 |

| 1018 | Corridors | 352 |

| 1019 | Egress Balconies | 354 |

| 1020 | Exits | 354 |

| 1021 | Number of Exits and Continuity | 354 |

| 1022 | Exit Enclosures | 355 |

| 1023 | Exit Passageways | 357 |

| 1024 | Luminous Egress Path Markings | 357 |

| 1025 | Horizontal Exits | 359 |

| 1026 | Exterior Exit Ramps and Stairways | 360 |

| 1027 | Exit Discharge | 360 |

| 1028 | Assembly | 361 |

| 1029 | Emergency Escape and Rescue | 366 |

| CHAPTER 11 RESERVED | 369 | |

| CHAPTER 11A HOUSING ACCESSIBILITY | 373 | |

| Section | ||

| 1101A | Application | 373 |

| 1102A | Building Accessibility | 373 |

| 1103A | Design and Construction | 374 |

| 1104A | Covered Multifamily Dwellings | 374 |

| 1105A | Garages, Carports and Parking Facilities | 375 |

| 1106A | Site and Building Characteristics | 375 |

| 1107A | Definitions | 375 |

| 1108A | General Requirements for Accessible Parking and Exterior Routes of Travel | 378 |

| 1109A | Parking Facilities | 378 |

| 1110A | Exterior Routes of Travel | 380 |

| 1111A | Changes in Level on Accessible Routes | 380 |

| 1112A | Curb Ramps on Accessible Routes | 381 |

| 1113A | Walks and Sidewalks on an Accessible Route | 381 |

| 1114A | Exterior Ramps and Landings on Accessible Routes | 382 |

| 1115A | Exterior Stairways | 383 |

| 1116A | Hazards on Accessible Routes | 384 |

| 1117A | General Requirements for Accessible Entrances, Exits, Interior Routes of Travel and Facility Accessibility | 385 |

| 1118A | Egress and Areas of Refuge | 385 |

| 1119A | Interior Routes of Travel | 385 |

| 1120A | Interior Accessible Routes | 385 |

| 1121A | Changes in Level on Accessible Routes | 386 |

| 1122A | Interior Ramps and Landings on Accessible Routes | 386 |

| 1123A | Interior Stairways | 387 |

| 1124A | Elevators and Platform (Wheelchair) Lifts | 388 |

| 1125A | Hazards on Accessible Routes | 390 |

| 1126A | Doors | 390 |

| 1127A | Common Use Facilities | 391 |

| 1128A | Covered Dwelling Units | 398 |

| 1129A | Reserved | 398 |

| 1130A | Accessible Route Within Covered Multifamily Dwelling Units | 398 |

| 1131A | Changes in Level on Accessible Routes | 398 |

| 1132A | Doors | 398 |

| 1133A | Kitchens | 400 |

| 1134A | Bathing and Toilet Facilities | 400 |

| 1135A | Laundry Rooms | 403 |

| 1136A | Electrical Receptacle, Switch and Control Heights | 403 |

| 1137A | Other Features and Facilities | 405 |

| 1138A | Reserved | 405 |

| 1139A | Accessible Drinking Fountains | 405 |

| 1140A | Accessible Telephones | 405 |

| 1141A | Accessible Swimming Pools | 406 |

| 1142A | Electrical Receptacle, Switch and Control Heights | 407 |

| 1143A | Signage | 407 |

| 1144A | Reserved | 408 |

| 1145A | Reserved | 408 |

| 1146A | Reserved | 408 |

| 1147A | Reserved | 408 |

| 1148A | Reserved | 408 |

| 1149A | Reserved | 408 |

| 1150A | Site Impracticality Tests | 409 |

| CHAPTER 11B ACCESSIBILITY TO PUBLIC BUILDINGS, PUBLIC ACCOMODATIONS, COMMERICAL BUILDINGS AND PUBLICLY FUNDED HOUSING | 465 | |

| Section | ||

| 1101B | Scope | 465 |

| 1102B | Definitions | 465 |

| 1103B | Building Accessibility | 468 |

| 1104B | Accessibility for Group A Occupancies | 469 |

| 1105B | Accessibility for Group B Occupancies | 472 |

| 1106B | Accessibility for Group E Occupancies | 473 |

| 1107B | Factories and Warehouses | 474 |

| 1108B | Accessibility for Group H Occupancies | 474 |

| 1109B | Accessibility for Group I Occupancies | 475 |

| 1110B | Accessibility for Group M Occupancies | 475 |

| 1111B | Accessibility for Group R Occupancies | 477 |

| 1112B | Reserved | 479 |

| 1113B | Reserved | 479 |

| 1114B | Facility Accessibility | 479 |

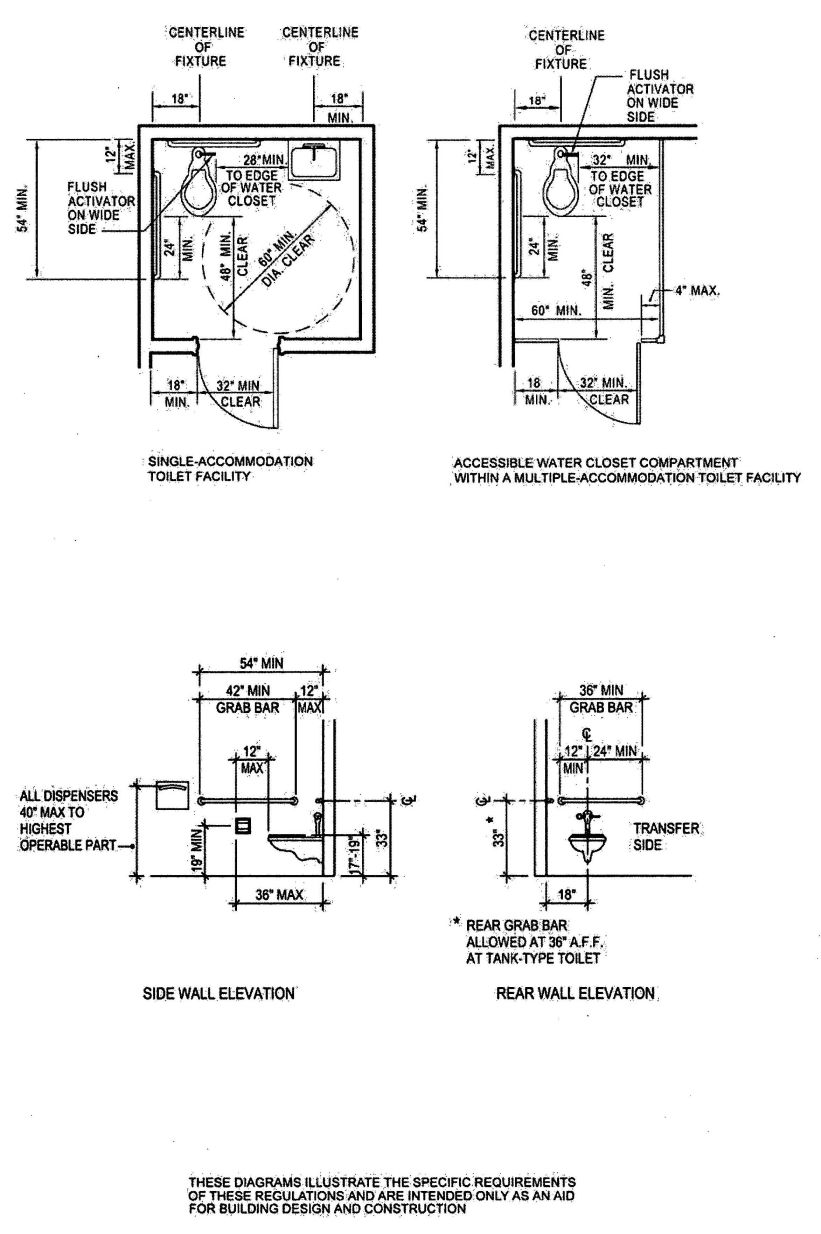

| 1115B | Bathing and Toilet Facilities (Sanitary Facilities) | 480 |

| 1116B | Elevators and Special Access (Wheelchair) Lifts | 486 |

| 1117B | Other Building Components | 489 |

| 1118B | Space Allowance and Reach Ranges | 497 |

| 1119B | Special Standards of Accessibility for Buildings with Historical Significance | 497 |

| 1120B | Floor and Levels | 497 |

| 1121B | Transportation Facilities | 498 |

| 1122B | Fixed or Built-in Seating, Tables and Counters | 501 |

| 1123B | Access to Employee Areas | 502 |

| 1124B | Ground and Floor Surfaces | 502 |

| 1125B | Storage | 502 |

| 1126B | Vending Machines and Other Equipment | 502 |

| 1127B | Exterior Routes of Travel | 503 |

| 1128B | Pedestrian Grade Separations (Overpasses and Underpasses) | 504 |

| 1129B | Accessible Parking Required | 504 |

| 1130B | Parking Structures | 506 |

| 1131B | Passenger Drop-off and Loading Zones | 506 |

| 1132B | Outdoor Occupancies | 506 |

| 1133B | General Accessibility for Entrances, Exits and Paths of Travel | 508 |

| 1134B | Accessibility for Existing Buildings | 515 |

| 1135B | Historic Preservation—Special Standards of Accessibility for Buildings with Historical Significance | 516 |

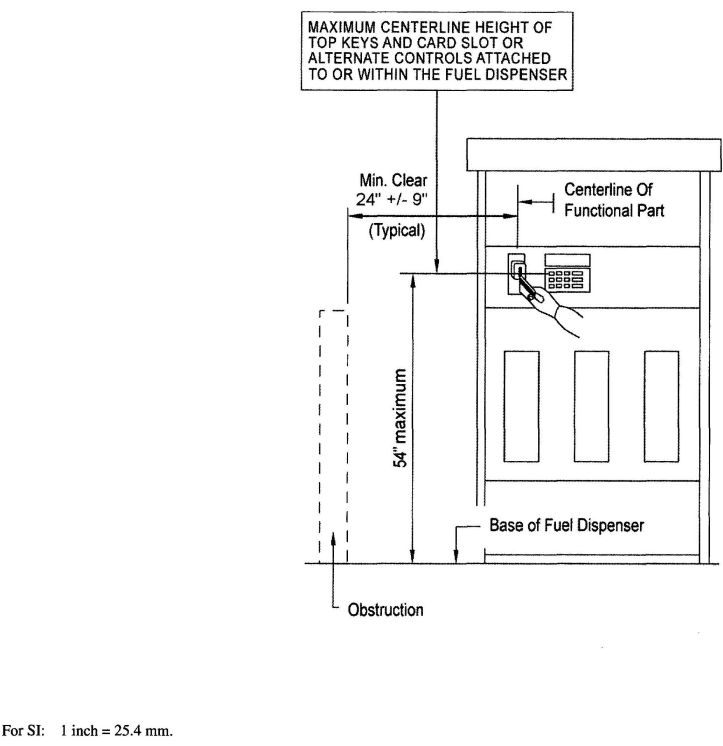

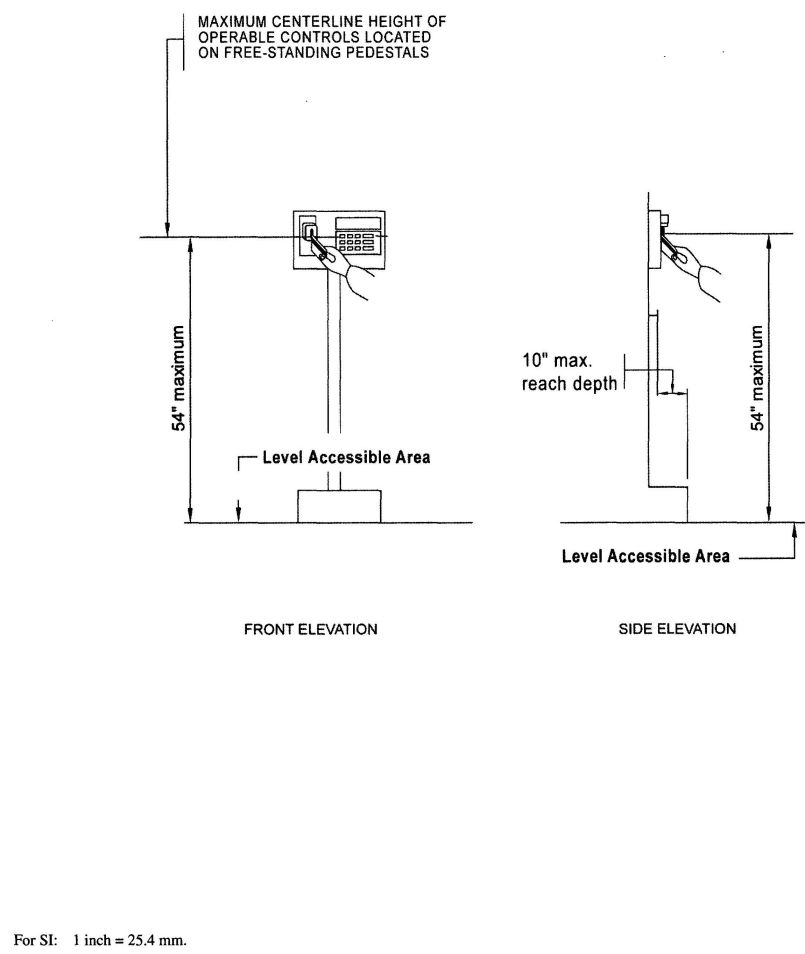

| CHAPTER 11C STANDARDS FOR CARD READERS AT GASOLINE FUEL-DISPENSING FACILITIES | 587 | |

| Section | ||

| 1101C | Card-Reader Devices at Fuel-Dispensing Equipment | 587 |

| 1102C | Application | 587 |

| 1103C | Number of Accessible Card-Reading Devices Required | 587 |

| 1104C | Required Features | 587 |

| CHAPTER 12 INTERIOR ENVIRONMENT | 593 | |

| Section | ||

| 1201 | General | 593 |

| 1202 | Definitions | 593 |

| 1203 | Ventilation | 593 |

| 1204 | Temperature Control | 594 |

| 1205 | Lighting | 595 |

| 1206 | Yards or Courts | 595 |

| 1207 | Sound Transmission | 596 |

| 1208 | Interior Space Dimensions | 598 |

| 1209 | Access to Unoccupied Spaces | 599 |

| 1210 | Surrounding Materials | 599 |

| 1211 | Garage Door Springs | 599 |

| 1212 | Reserved | 600 |

| 1213 | Reserved | 600 |

| 1214 | Reserved | 600 |

| 1215 | Reserved | 600 |

| 1216 | Reserved | 600 |

| 1217 | Reserved | 600 |

| 1218 | Reserved | 600 |

| 1219 | Reserved | 600 |

| 1220 | Reserved | 600 |

| 1221 | Reserved | 600 |

| 1222 | Reserved | 600 |

| 1223 | Reserved | 600 |

| 1224 | Hospitals | 600 |

| 1225 | Skilled Nursing and Intermediate-Care Facilities | 628 |

| 1226 | Clinics | 633 |

| 1227 | Correctional Treatment Centers | 636 |

| 1228 | Reserved | 641 |

| 1229 | Reserved | 641 |

| 1230 | Minimum Standards for Juvenile Facilities | 641 |

| 1231 | Local Detention | 645 |

| 1232 | Reserved | 651 |

| 1233 | Reserved | 651 |

| 1234 | Reserved | 651 |

| 1235 | Sanitary Control of Shellfish (Plants and Operations) | 651 |

| 1236 | Laboratory Animal Quarters | 651 |

| 1237 | Wild Animal Quarantine Facilities | 652 |

| 1238 | Reserved | 652 |

| 1239 | Reserved | 652 |

| 1240 | Meat and Poultry Processing Plants | 652 |

| 1241 | Collection Centers and Facilities | 654 |

| 1242 | Renderers | 654 |

| 1243 | Horsemeat and Pet Food Establishments | 654 |

| 1244 | Reserved | 655 |

| 1245 | Reserved | 655 |

| 1246 | Reserved | 655 |

| 1247 | Reserved | 655 |

| 1248 | Reserved | 655 |

| 1249 | Reserved | 655 |

| 1250 | Pharmacies | 655 |

| 1251 | Veterinary Facilities | 655 |

| 1252 | Barber Colleges and Shops | 656 |

| 1253 | Schools of Cosmetology, Cosmetological Establishments and Satellite Classrooms | 656 |

| 1254 | Acupuncture Offices | 657 |

| CHAPTER 13 ENERGY EFFICIENCY | 659 | |

| CHAPTER 14 EXTERIOR WALLS | 663 | |

| Section | ||

| 1401 | General | 663 |

| 1402 | Definitions | 633 |

| 1403 | Performance Requirements | 663 |

| 1404 | Materials | 664 |

| 1405 | Installation of Wall Coverings | 665 |

| 1406 | Combustible Materials on the Exterior Side of Exterior Walls | 669 |

| 1407 | Metal Composite Materials (MCM) | 670 |

| 1408 | Exterior Insulation and Finish Systems (EIFS) | 671 |

| 1409 | [DSA-SS and DSA-SS⁄CC, OSHPD 1,2 & 4] Additional Requirements for Anchored and Adhered Veneer | 671 |

| CHAPTER 15 ROOF ASSEMBLIES AND ROOFTOP STRUCTURES | 675 | |

| Section | ||

| 1501 | General | 675 |

| 1502 | Definitions | 675 |

| 1503 | Weather Protection | 675 |

| 1504 | Performance Requirements | 676 |

| 1505 | Fire Classification | 677 |

| 1506 | Materials | 678 |

| 1507 | Requirements for Roof Coverings | 678 |

| 1508 | Roof Insulation | 687 |

| 1509 | Rooftop Structures | 688 |

| 1510 | Reroofing | 689 |

| 1511 | [DSA-SS and OSHPD 1,2 & 4] Seismic Anchorage of Slate Shingle, Clay and Concrete Tile Roof Coverings | 690 |

| INDEX | 691 | |

| HISTORY NOTE | 731 | |

| VOLUME 2 | ||

| CHAPTER 16 STRUCTURAL DESIGN | 5 | |

| Section | ||

| 1601 | General | 5 |

| 1602 | Definitions and Notations | 5 |

| 1603 | Construction Documents | 6 |

| 1604 | General Design Requirements | 7 |

| 1605 | Load Combinations | 10 |

| 1606 | Dead Loads | 11 |

| 1607 | Live Loads | 11 |

| 1608 | Snow Loads | 17 |

| 1609 | Wind Loads | 20 |

| 1610 | Soil Lateral Loads | 33 |

| 1611 | Rain Loads | 34 |

| 1612 | Flood Loads | 40 |

| 1613 | Earthquake Loads | 42 |

| 1614 | Structural Integrity | 48 |

| 1615 | Additional Requirements [DSA-SS/CC] | 69 |

| CHAPTER 16A STRUCTURAL DESIGN | 79 | |

| Section | ||

| 1601A | General | 79 |

| 1602A | Definitions and Notations | 79 |

| 1603A | Construction Documents | 81 |

| 1604A | General Design Requirements | 82 |

| 1605A | Load Combinations | 84 |

| 1606A | Dead Loads | 86 |

| 1607A | Live Loads | 86 |

| 1608A | Snow Loads | 91 |

| 1609A | Wind Loads | 94 |

| 1610A | Soil Lateral Loads | 104 |

| 1611A | Rain Loads | 104 |

| 1612A | Flood Loads | 110 |

| 1613A | Earthquake Loads | 112 |

| 1614A | Structural Integrity | 117 |

| 1615A | Modifications to ASCE 7 | 119 |

| CHAPTER 17 STRUCTURAL TESTS AND SPECIAL INSPECTIONS | 129 | |

| Section | ||

| 1701 | General | 129 |

| 1702 | Definitions | 129 |

| 1703 | Approvals | 129 |

| 1704 | Special Inspections | 130 |

| 1705 | Statement of Special Inspections | 141 |

| 1706 | Special Inspections for Wind Requirements | 143 |

| 1707 | Special Inspections for Seismic Resistance | 143 |

| 1708 | Structural Testing for Seismic Resistance | 144 |

| 1709 | Contractor Responsibility | 145 |

| 1710 | Structural Observations | 145 |

| 1711 | Design Strengths of Materials | 145 |

| 1712 | Alternative Test Procedure | 145 |

| 1713 | Test Safe Load | 146 |

| 1714 | In-situ Load Tests | 146 |

| 1715 | Preconstruction Load Tests | 146 |

| 1716 | Material and Test Standards | 147 |

| CHAPTER 17A STRUCTURAL TESTS AND SPECIAL INSPECTIONS | 151 | |

| Section | ||

| 1701A | General | 151 |

| 1702A | Definitions | 151 |

| 1703A | Approvals | 152 |

| 1704A | Special Inspections | 153 |

| 1705A | Statement of Special Inspections | 165 |

| 1706A | Special Inspections for Wind Requirements | 167 |

| 1707A | Special Inspections for Seismic Resistance | 167 |

| 1708A | Structural Testing for Seismic Resistance | 168 |

| 1709A | Contractor Responsibility | 169 |

| 1710A | Structural Observations | 169 |

| 1711A | Design Strengths of Materials | 169 |

| 1712A | Alternative Test Procedure | 170 |

| 1713A | Test Safe Load | 170 |

| 1714A | In-situ Load Tests | 170 |

| 1715A | Preconstruction Load Tests | 170 |

| 1716A | Material and Test Standards | 171 |

| CHAPTER 18 SOILS AND FOUNDATIONS | 175 | |

| Section | ||

| 1801 | General | 175 |

| 1802 | Definitions | 175 |

| 1803 | Geotechnical Investigations | 175 |

| 1804 | Excavation, Grading and Fill | 178 |

| 1805 | Dampproofing and Waterproofing | 179 |

| 1806 | Presumptive Load-Bearing Values of Soils | 180 |

| 1807 | Foundation Walls, Retaining Walls and Embedded Posts and Poles | 181 |

| 1808 | Foundations | 187 |

| 1809 | Shallow Foundations | 189 |

| 1810 | Deep Foundations | 192 |

| CHAPTER 18A SOILS AND FOUNDATIONS | 207 | |

| Section | ||

| 1801A | General | 207 |

| 1802A | Definitions | 207 |

| 1803A | Geotechnical Investigations | 208 |

| 1804A | Excavation, Grading and Fill | 211 |

| 1805A | Dampproofing and Waterproofing | 211 |

| 1806A | Presumptive Load-Bearing Values of Soils | 213 |

| 1807A | Foundation Walls, Retaining Walls and Embedded Posts and Poles | 213 |

| 1808A | Foundations | 215 |

| 1809A | Shallow Foundations | 218 |

| 1810A | Deep Foundations | 219 |

| 1811A | Prestressed Rock and Soil Foundation Anchors | 231 |

| CHAPTER 19 CONCRETE | 235 | |

| Section | ||

| 1901 | General | 235 |

| 1902 | Definitions | 235 |

| 1903 | Specifications for Tests and Materials | 235 |

| 1904 | Durability Requirements | 236 |

| 1905 | Concrete Quality, Mixing and Placing | 236 |

| 1906 | Formwork, Embedded Pipes and Construction Joints | 238 |

| 1907 | Details of Reinforcement | 238 |

| 1908 | Modifications to ACI 318 | 239 |

| 1909 | Structural Plain Concrete Not Permitted by OSHPD and DSA-SS | 241 |

| 1910 | Minimum Slab Provisions | 242 |

| 1911 | Anchorage to Concrete—Allowable Stress Design | 242 |

| 1912 | Anchorage to Concrete—Strength Design | 243 |

| 1913 | Shotcrete | 244 |

| 1914 | Reinforced Gypsum Concrete | 245 |

| 1915 | Concrete-Filled Pipe Columns | 245 |

| 1916 | Additional Requirements [DSA-SS/CC] | 246 |

| CHAPTER 19A CONCRETE | 253 | |

| Section | ||

| 1902A | General | 253 |

| 1902A | Definitions | 253 |

| 1903A | Specifications for Tests and Materials | 255 |

| 1904A | Durability Requirements | 255 |

| 1905A | Concrete Quality, Mixing and Placing | 256 |

| 1906A | Formwork, Embedded Pipes and Construction Joints | 257 |

| 1907A | Details of Reinforcement | 257 |

| 1908A | Modifications to ACI 318 | 258 |

| 1909A | Structural Plain Concrete Not Permitted by OSHPD and DSA-SS | 262 |

| 1910A | Minimum Slab Provisions | 262 |

| 1911A | Anchorage to Concrete—Allowable Stress Design | 263 |

| 1912A | Anchorage to Concrete—Strength Design | 263 |

| 1913A | Shotcrete | 264 |

| 1914A | Reinforced Gypsum Concrete | 265 |

| 1915A | Concrete-Filled Pipe Columns | 265 |

| 1916A | Concrete, Reinforcement and Anchor Testing | 266 |

| 1917A | Existing Concrete Structures | 267 |

| CHAPTER 20 ALUMINUM | 271 | |

| Section | ||

| 2001 | General | 271 |

| 2002 | Materials | 271 |

| 2003 | Inspection | 271 |

| CHAPTER 21 MASONRY | 275 | |

| Section | ||

| 2101 | General | 275 |

| 2102 | Definitions and Notations | 275 |

| 2103 | Masonry Construction Materials | 278 |

| 2104 | Construction | 280 |

| 2105 | Quality Assurance | 280 |

| 2106 | Seismic Design | 281 |

| 2107 | Allowable Stress Design | 282 |

| 2108 | Strength Design of Masonry | 282 |

| 2109 | Empirical Design of Masonry | 282 |

| 2110 | Glass Unit Masonry | 284 |

| 2111 | Masonry Fireplaces | 284 |

| 2112 | Masonry Heaters | 287 |

| 2113 | Masonry Chimneys | 287 |

| 2114 | Additional Requirements [DSA-SS/CC] | 291 |

| CHAPTER 21A MASONRY | 297 | |

| Section | ||

| 2101A | General | 297 |

| 2102A | Definitions and Notations | 298 |

| 2103A | Masonry Construction Materials | 301 |

| 2104A | Construction | 302 |

| 2105A | Quality Assurance | 305 |

| 2106A | Seismic Design | 306 |

| 2107A | Allowable Stress Design | 307 |

| 2108A | Strength Design of Masonry | 308 |

| 2109A | Empirical Design of Masonry Not Permitted by OSHPD and DSA-SS | 309 |

| 2110A | Glass Unit Masonry | 309 |

| 2111A | Masonry Fireplaces | 309 |

| 2112A | Masonry Heaters | 311 |

| 2113A | Masonry Chimneys | 312 |

| 2114A | Nonbearing Walls | 316 |

| 2115A | Masonry Screen Walls | 316 |

| CHAPTER 22 STEEL | 319 | |

| Section | ||

| 2201 | General | 319 |

| 2202 | Definitions | 319 |

| 2203 | Identification and Protection of Steel for Structural Purposes | 319 |

| 2204 | Connections | 319 |

| 2205 | Structural Steel | 320 |

| 2206 | Steel Joists | 320 |

| 2207 | Steel Cable Structures | 321 |

| 2208 | Steel Storage Racks | 321 |

| 2209 | Cold-Formed Steel | 321 |

| 2210 | Cold-Formed Steel Light-Frame Construction | 321 |

| 2211 | Additional Requirements [DSA-SS/CC] | 322 |

| CHAPTER 22A STEEL | 327 | |

| Section | ||

| 2201A | General | 327 |

| 2202A | Definitions | 327 |

| 2203A | Identification and Protection of Steel for Structural Purposes | 327 |

| 2204A | Connections | 327 |

| 2205A | Structural Steel | 328 |

| 2206A | Steel Joists | 330 |

| 2207A | Steel Cable Structures | 331 |

| 2208A | Steel Storage Racks | 331 |

| 2209A | Cold-Formed Steel | 331 |

| 2210A | Cold-Formed Steel Light-Framed Construction | 331 |

| 2211A | Light Modular Steel Moment Frames for Public Elementary and Secondary Schools, and Community Colleges | 331 |

| 2212A | Testing | 333 |

| CHAPTER 23 WOOD | 337 | |

| Section | ||

| 2301 | General | 337 |

| 2302 | Definitions | 337 |

| 2303 | Minimum Standards and Quality | 339 |

| 2304 | General Construction Requirements | 343 |

| 2305 | General Design Requirements for Lateral-Force-Resisting Systems | 354 |

| 2306 | Allowable Stress Design | 357 |

| 2307 | Load and Resistance Factor Design | 358 |

| 2308 | Conventional Light-Frame Construction | 358 |

| CHAPTER 24 GLASS AND GLAZING | 411 | |

| Section | ||

| 2401 | General | 411 |

| 2402 | Definitions | 411 |

| 2403 | General Requirements for Glass | 411 |

| 2404 | Wind, Snow, Seismic and Dead Loads on Glass | 411 |

| 2405 | Sloped Glazing and Skylights | 413 |

| 2406 | Safety Glazing | 415 |

| 2407 | Glass in Handrails and Guards | 417 |

| 2408 | Glazing in Athletic Facilities | 417 |

| 2409 | Glass in Elevator Hoistways and Elevator Cars | 417 |

| CHAPTER 25 GYPSUM BOARD AND PLASTER | 421 | |

| Section | ||

| 2501 | General | 421 |

| 2502 | Definitions | 421 |

| 2503 | Inspection | 421 |

| 2504 | Vertical and Horizontal Assemblies | 421 |

| 2505 | Shear Wall Construction | 422 |

| 2506 | Gypsum Board Materials | 422 |

| 2507 | Lathing and Plastering | 422 |

| 2508 | Gypsum Construction | 423 |

| 2509 | Gypsum Board in Showers and Water Closets | 424 |

| 2510 | Lathing and Furring for Cement Plaster (Stucco) | 424 |

| 2511 | Interior Plaster | 425 |

| 2512 | Exterior Plaster | 425 |

| 2513 | Exposed Aggregate Plaster | 426 |

| CHAPTER 26 PLASTIC | 431 | |

| Section | ||

| 2601 | General | 431 |

| 2602 | Definitions | 431 |

| 2603 | Foam Plastic Insulation | 431 |

| 2604 | Interior Finish and Trim | 434 |

| 2605 | Plastic Veneer | 435 |

| 2606 | Light-transmitting Plastics | 435 |

| 2607 | Light-transmitting Plastic Wall Panels | 436 |

| 2608 | Light-transmitting Plastic Glazing | 437 |

| 2609 | Light-transmitting Plastic Roof Panels | 437 |

| 2610 | Light-transmitting Plastic Skylight Glazing | 438 |

| 2611 | Light-transmitting Plastic Interior Signs | 439 |

| 2612 | Fiber Reinforced Polymer and Fiberglass-reinforced Polymer | 439 |

| 2613 | Reflective Plastic Core Insulation | 440 |

| CHAPTER 27 ELECTRICAL | 443 | |

| Section | ||

| 2701 | General | 443 |

| 2702 | Emergency and Standby Power Systems | 443 |

| CHAPTER 28 MECHANICAL SYSTEMS | 447 | |

| Section | ||

| 2801 | General | 447 |

| CHAPTER 29 PLUMBING SYSTEMS | 449 | |

| Section | ||

| 2901 | General | 449 |

| CHAPTER 30 ELEVATORS AND CONVEYING SYSTEMS | 30 | |

| Section | ||

| 3001 | General | 30 |

| 3002 | Hoistway Enclosures | 30 |

| 3003 | Emergency Operations | 456 |

| 3004 | Hoistway Venting | 457 |

| 3005 | Conveying Systems | 457 |

| 3006 | Machine Rooms | 458 |

| 3007 | Fire Service Access Elevator | 458 |

| 3008 | Occupant Evacuation Elevators | 459 |

| 3009 | Special Requirements for Elevators in Hospitals | 460 |

| CHAPTER 31 SPECIAL CONSTRUCTION | 465 | |

| Section | ||

| 3101 | General | 465 |

| 3102 | Membrane Structures | 465 |

| 3103 | Temporary Structures | 466 |

| 3104 | Pedestrian Walkways and Tunnels | 466 |

| 3105 | Awnings and Canopies | 467 |

| 3106 | Marquees | 468 |

| 3107 | Signs | 468 |

| 3108 | Telecommunication and Broadcast Towers | 468 |

| 3109 | Swimming Pool Enclosures and Safety Devices | 468 |

| 3110 | Automatic Vehicular Gates | 472 |

| CHAPTER 31A RESERVED | 473 | |

| CHAPTER 31B PUBLIC SWIMMING POOLS | 477 | |

| Section | ||

| 3101B | Scope | 477 |

| 3102B | Definitions | 477 |

| 3103B | Special Pool Classifications | 478 |

| 3104B | Accessibility to the Physically Handicapped Person | 478 |

| 3105B | Alternate Equipment, Materials and Methods of Construction | 478 |

| 3106B | Pool Construction | 478 |

| 3107B | Additional Requirements for a Temporary Training Pool | 479 |

| 3108B | Pool Geometry | 479 |

| 3109B | Permanent Markings | 479 |

| 3110B | Steps, Recessed Steps, Ladders and Recessed Stairs (Treads) | 482 |

| 3111B | Handholds | 483 |

| 3112B | Diving Boards | 483 |

| 3113B | Pool Decks | 483 |

| 3114B | Pool Lighting | 483 |

| 3115B | Bathhouse Dressing, Shower and Toilet Facilities | 484 |

| 3116B | Drinking Fountains | 484 |

| 3117B | Hose Bibbs | 484 |

| 3118B | Enclosure of Pool Area | 484 |

| 3119B | Signs | 485 |

| 3120B | Indoor Pool Ventilation | 487 |

| 3121B | Foundations For Pool Equipment | 487 |

| 3122B | Gas Chlorination Equipment Room | 487 |

| 3123B | General Requirements | 487 |

| 3124B | Turnover Time | 487 |

| 3125B | Recirculation Piping System and Components | 487 |

| 3126B | Recirculation Pump Capacity | 488 |

| 3127B | Water Supply Inlets | 488 |

| 3128B | Filters (All Types) | 488 |

| 3129B | Rapid Sand Pressure Filters | 488 |

| 3130B | Diatomaccous Earth Filters | 489 |

| 3131B | High-rate Sand Filters | 489 |

| 3132B | Chemical Feeders | 489 |

| 3133B | Disinfectant Feeders | 489 |

| 3134B | Pool Fittings | 490 |

| 3135B | Spa Pool Special Requirements | 491 |

| 3136B | Cleaning Systems | 491 |

| 3137B | Waste Water Disposal | 491 |

| 3138B | Reserved | 491 |

| 3139B | Reserved | 491 |

| 3140B | Reserved | 491 |

| 3141B | Reserved | 491 |

| 3142B | Reserved | 491 |

| 3143B | Reserved | 491 |

| 3144B | Reserved | 491 |

| 3145B | Reserved | 491 |

| 3146B | Reserved | 492 |

| 3147B | Reserved | 492 |

| 3148B | Reserved | 492 |

| 3149B | Reserved | 492 |

| 3150B | Reserved | 492 |

| 3151B | Reserved | 492 |

| 3152B | Reserved | 492 |

| 3153B | Reserved | 492 |

| 3154B | Reserved | 492 |

| 3155B | Reserved | 492 |

| 3156B | Reserved | 492 |

| 3157B | Reserved | 492 |

| 3158B | Reserved | 492 |

| 3159B | Reserved | 492 |

| 3160B | 492 | |

| 3161B | 492 | |

| 3162B | Anti-Entrapment Devices and Systems | 493 |

| CHAPTER 31C RADIATION | 499 | |

| Section | ||

| 3101C | Scope | 499 |

| 3102C | Radiation Shielding Barriers | 499 |

| 3103C | Medical Radiographic and Photofluorographic Installations | 499 |

| 3104C | Medical Therapeutic X-ray Installations | 499 |

| CHAPTER 31D FOOD ESTABLISHMENTS | 503 | |

| Section | ||

| 3101D | Scope | 503 |

| 3102D | Definitions | 503 |

| 3103B | Building and Structures | 503 |

| CHAPTER 31E RESERVED | 505 | |

| CHAPTER 31F MARINE OIL TERMINALS | 509 | |

| Section | ||

| 3101F | Introduction | 509 |

| 3102F | Audit and Inspection | 510 |

| 3103F | Structural Loading Criteria | 521 |

| 3104F | Seismic Analysis and Structural Performance | 536 |

| 3105F | Mooring and Berthing Analysis and Design | 543 |

| 3106F | Geotechnical Hazards and Foundations | 548 |

| 3107F | Structural Analysis and Design of Components | 552 |

| 3108F | Fire Prevention, Detection and Suppression | 566 |

| 3109F | Piping and Pipelines | 570 |

| 3110F | Mechanical and Electrical Equipment | 573 |

| 3111F | Electrical Systems | 576 |

| CHAPTER 32 ENCROACHMENTS INTO THE PUBLIC RIGHT-OF-WAY | 581 | |

| Section | ||

| 3201 | General | 581 |

| 3202 | Encroachments | 581 |

| CHAPTER 33 SAFEGUARDS DURING CONSTRUCTION | 585 | |

| Section | ||

| 3301 | General | 585 |

| 3302 | Construction Safeguards | 585 |

| 3303 | Demolition | 585 |

| 3304 | Site Work | 585 |

| 3305 | Sanitary | 585 |

| 3306 | Protection of Pedestrians | 586 |

| 3307 | Protection of Adjoining Property | 587 |

| 3308 | Temporary Use of Streets, Alleys and Public Property | 587 |

| 3309 | Fire Extinguishers | 587 |

| 3310 | Means of Egress | 588 |

| 3311 | Standpipes | 588 |

| 3312 | Automatic Sprinkler System | 588 |

| CHAPTER 34 EXISTING STRUCTURES | 591 | |

| Section | ||

| 3401 | General | 591 |

| 3402 | Definitions | 592 |

| 3403 | Additions | 593 |

| 3404 | Alterations | 593 |

| 3405 | Repairs | 594 |

| 3406 | Fire Escapes | 596 |

| 3407 | Glass Replacement | 596 |

| 3408 | Change of Occupancy | 596 |

| 3409 | Historic Buildings | 597 |

| 3410 | Moved Structures | 597 |

| 3411 | Accessibility for Existing Buildings | 597 |

| 3412 | Compliance Alternatives | 599 |

| 3413 | Existing Group R-1 and Group R-2 Occupancies [SFM] | 608 |

| 3414 | Existing High-Rise Buildings [SFM] | 611 |

| 3415 | Existing Group I Occupancies [SFM] | 613 |

| 3416 | Existing Group L Occupancies [SFM] | 614 |

| 3417 | Earthquake Evaluation and Design for Retrofit of Existing Buildings | 614 |

| 3418 | Definitions | 617 |

| 3419 | Seismic Criteria Selectionfor Existing Buildings | 618 |

| 3420 | Method A | 621 |

| 3421 | Method B | 621 |

| 3422 | Peer Review Requirements | 622 |

| 3423 | Additional Requirements for Public Schools and Community Colleges | 623 |

| CHAPTER 34A EXISTING STRUCTURES | 627 | |

| Section | ||

| 3401A | General | 627 |

| 3402A | Definitions | 627 |

| 3403A | Additions | 628 |

| 3404A | Alterations | 629 |

| 3405A | Repairs | 630 |

| 3406A | Fire Escapes | 631 |

| 3407A | Glass Replacement | 631 |

| 3408A | Change of Occupancy | 631 |

| 3409A | Historic Buildings | 632 |

| 3410A | Moved Structures | 632 |

| 3411A | Additions, Alterations, Repairs and Seismic Retrofit to Existing Buildings or Structures Designed in Accordance with Pre-1973 Building Code | 632 |

| 3412A | Compliance Alternatives for Additions, Alterations, Repairs and Seismic Retrofit to Existing Structures | 632 |

| 3413A | Modifications to ASCE 41 | 634 |

| 3414A | Peer Review Requirements | 636 |

| 3415A | Earthquake Monitoring Instruments for Existing Buildings | 637 |

| CHAPTER 35 REFERENCED STANDARDS | 641 | |

| APPENDIX A EMPLOYEE QUALIFICATIONS | 671 | |

| Section | ||

| A101 | Building Official Qualifications | 671 |

| A102 | Referenced Standards | 671 |

| APPENDIX B BOARD OF APPEALS | 675 | |

| Section | ||

| B101 | General | 675 |

| APPENDIX C GROUP U—AGRICULTURAL BUILDINGS | 679 | |

| Section | ||

| C101 | General | 679 |

| C102 | Allowable Height and Area | 679 |

| C103 | Mixed Occupancies | 679 |

| C104 | Exits | 679 |

| APPENDIX D FIRE DISTRICTS | 683 | |

| Section | ||

| D101 | General | 683 |

| D102 | Building Restrictions | 683 |

| D103 | Changes to Buildings | 684 |

| D104 | Buildings Located Partially in the Fire District | 684 |

| D105 | Exceptions to Restrictions in Fire District | 684 |

| D106 | Referenced Standards | 685 |

| APPENDIX E RESERVED | 689 | |

| APPENDIX F RODENTPROOFING | 693 | |

| Section | ||

| F101 | General | 693 |

| APPENDIX G FLOOD-RESISTANT CONSTRUCTION | 697 | |

| Section | ||